The ECUMaster PMU-16 is one of our latest offerings at LMS-EFI.

SO WHAT IS THE PMU-16?

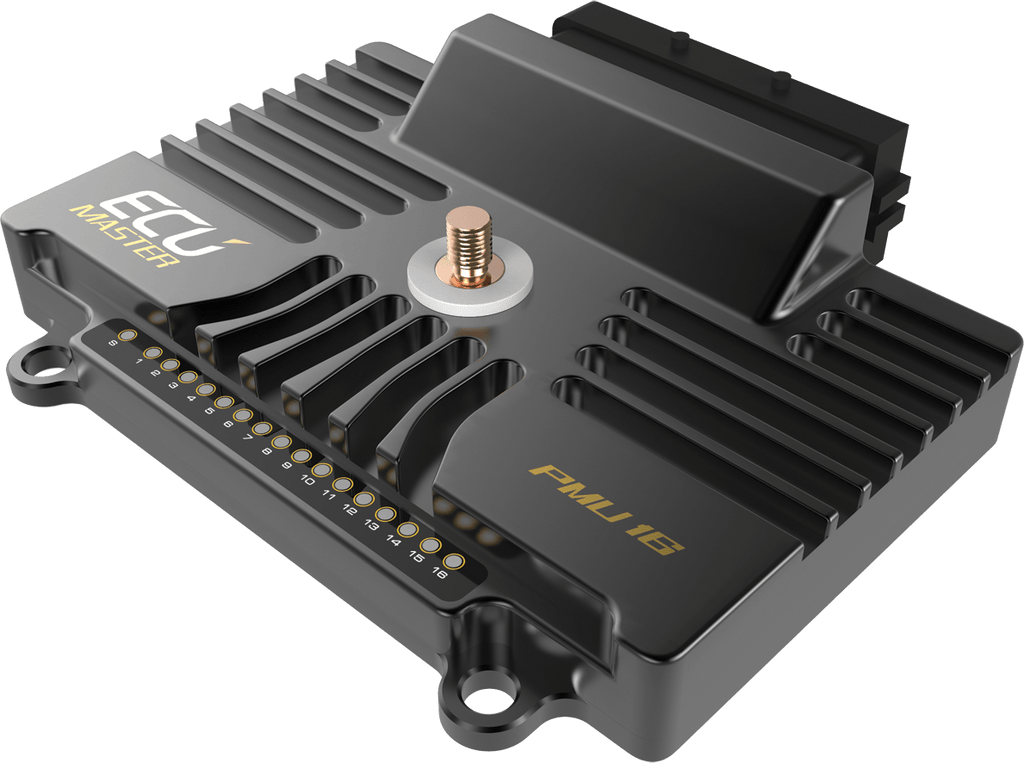

The ECUMaster PMU-16 is one of the newest players in the power distribution module arena. It packs an amazing amount of features into a small and affordable package. The case measures only 5.2"x4.4"x1.3" yet allows for 16 output channels (10 25A and 6 15A) and continuous 150A capacity. At LMS, we believe we shouldn't sell something we haven't used and proven ourselves, so we've employed this little guy to do some work within an established package and we're here to report the results.

Over the last several years, solid state power distribution modules have become more common in the automotive performance and racing aftermarket. On the surface, these boxes replace traditional fuses and relays but they are capable of so much more. The PMU-16, for example, allows the user to monitor amp draw and voltage on each individual circuit and set limits for over and under current accordingly. In rush draw is accounted for and user defined. Soft start capability is provided for large draw items, such as cooling fans, to avoid large system draw downs when those items are turned on. PWM output is available, which means the user can control speeds of inductive motors directly through the PMU without the need for external solid state relays. Fans can be run in closed loop, for example, and only run as fast as needed to accurately control temps and prevent spikes in temperatures. CAN bus and analog communication is provided to communicate with the other control units in the system and whatever sensors the user deems necessary to produce proper control logic. At the end of the day, the PMU is capable of so much more than what can be done with simple fuse and relay technology.

Additional features beyond simple power management include integrated 3-axis accelerometer and yaw sensor. These can be linked to the ECU via CAN bus for use in power engine management and traction control. Additionally, there is a crash detection function built in to the PMU so that power will be shutdown if a programmed G load limit is exceeded. Status lights are integrated into the case for each output channel showing current channel function allowing increased ease of troubleshooting. The billet aluminum case is IP-65 rated for water and dust intrusion resistance.

The software contains an integral CAN bus monitor that allows the user to diagnose and decode unfamiliar CAN protocols. If you don't have information on the protocol you're reading, diligent effort can be employed to deconstruct the protocol and write functions into the PMU-16 to work with a wide variety of systems. With the PMU-16, there is no need for 3rd party software or equipment to accomplish this.

The PMU is available in two models, the PMU-16 and PMU-16DL. Both are identical in terms of power management function. The DL model contains an integrated data logger. The logger has a 256MB capacity and can log any channel at up to 500Mhz. Logging is not limited to the power management but is open to anything available on the CAN bus. So the PMU-16DL can be used as a one source logger for an entire chassis, if desired.

WHAT HAS LMS-EFI DONE WITH THE PMU-16?

In short, this is one product that has done everything correctly right from the start. We have had zero issues with the box itself or the software interface. We dreamed up control strategies, programmed the CAN bus interface to communicate with 3rd party ECU and dash displays, and it worked. The dedicated competition car we worked with for this prove out didn't have a need for things like turn signal blinkers or windshield wipers. However, blinkers are easy enough to program and there is a dedicated wiper function, with park logic, for street car use. So what did we do?

Cooling Fans - This car was equipped with two fans. One two-speed fan on the radiator and one single-speed fan on the oil cooler. We used simple digital on/off logic for these fans triggering them based on coolant and oil temp received over CAN bus from the ECU. This is the most basic control structure. We could have chosen PWM speed control of the fans but we just didn't feel it was necessary. Interestingly, one thing the PMU and software allowed us to do is monitor current draw in real time. I never would have guessed the fan would draw around 75A on start up and close to 20A continuously in high speed mode. The software also allows you to monitor total system draw, which would probably be eye opening for most anyone that's never sat down and tried to add up all the systems on a modern EFI car.

Water Pump - This car uses an electric water pump. We decided on PWM control for this pump to control pump speed and as a result, fluid volume. Easy enough to setup a turn on point, base duty cycle, and temperature point for 100% duty. The software allows easy manipulation of these points to dial in responsiveness.

Fuel Pump - The fuel pump power is turned on/off in digital format based on a CAN bus signal from the ECU. Interestingly, we're using a pump that allows speed control via a PWM signal. This signal is controlled by the Syvecs ECU in a closed-loop manner. We program a pressure target for the ECU and the ECU then controls to PWM signal to the pump to maintain the target pressure.

Intercooler Pump - The water to air intercooler uses an electric pump to circulate water from the ice box. Again, we chose a digital on/off control structure based on intake air temp and throttle position. Control logic is limited only to your imagination. You could add run time, engine temp, MAP, or any function your desire to the control logic for any output.

Power Steering Pump - This is one of the coolest functions related to the PMU-16. This car uses a Toyota electric power steering pump. This pump can pull over 50A continuously so we used 3 of the 25A outputs ganged together to control the pump. The PMU-16 allows the user to gang up to 3 outputs together in this manner to increase total load capacity of any given function. Additionally, we're using PWM control on this output to vary the speed of the power steering pump. This gives us true variable assist power steering. Right now we simply have this function running based on wheel speed. The faster the car moves, the lower the assist rate. We could add functions for steering angle, lateral G, etc., but haven't yet seen the need to do so.

ECU and Display Dash - The Syvecs S8 ECU and Plex SDM-500 dash all share information with the PMU-16. The programmable nature of the CAN bus on all three manufacturer's products makes it possible to share information, which greatly decreases the number of sensors and wires necessary to produce a proper control structure. No need for proprietary sensors and modules as some manufacture's require.

Ignition and Injection - Again, with the software, we can easily and closely monitor the exact current draw from the ignition and injectors. This is very helpful for diagnostic work and somewhat eye opening to see what is actually happening during extended high load operation.

THE KEYPAD!

The 12-key ECUMaster keypad is fully sealed and IP-67 rated to be impervious to dust and water. This keypad communicates via CAN bus with the PMU to allow manual control of functions and SO MUCH MORE! Each button has 3 color, programmable back lighting. The buttons can be used as on/off latching, on/off momentary contact, 3-position radio button, or as simple display lights. The logo on each button can be changed and ECUMaster offers a wide variety of logos to customize each key function.

So what did we do with the keypad? We have a master on/off button which takes the place of the ignition key and a start button for the starter. We chose to allow manual momentary contact for the starter but it would be easily possible to setup a control function for one-touch auto-starting fairly easily. Other buttons allow for manual override of fans and pumps. One button is used simply as a check engine light display to display a red light in the event any errors are detected with the PMU or Syvecs S8 ECU. One warning light also illuminates when coolant and/or oil temp are out of range. The light is green when temps are normal, orange when below operating temp, and red when over operating temp. We're considering using the keypad to adjust CAL or traction control calibration in the Syvecs ECU but haven't attempted to implement those features yet.

Conclusions

At the end of the day, the PMU-16 just works. It's been a rare treat in the world of aftermarket engine management to have something function as advertised at every turn. We look forward to implementing more of these units in the future and building on our knowledge base of CAN integration with 3rd parties and control functions. It's been fun to work with a product that allows us to do everything we want and not be hampered by proprietary functions and accessories that do not allow integration with other 3rd party units. Contact LMS-EFI today to see how the PMU-16 can work for you.